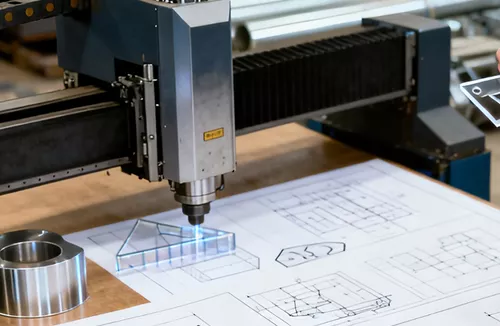

Laser cutting is a precise manufacturing process that uses a high-powered laser beam to cut materials into custom shapes with clean edges and tight tolerances. It’s ideal for both rapid prototyping and full-scale industrial production.

Advanced 2d laser cutting services

Fast, precise laser cutting for aluminum, acrylic, ABS plastic, foam and more. Get instant quoting and a free DFM review within 8 hours.

◉From Rapid Prototyping to Production

◉Tight Tolerances and Clean Edges

◉High-quality Laser Cut Parts in Days

Get An Instant Quote