A:The cost of a plastic injection mold depends on several factors, including the complexity of the part, mold size, number of cavities, type of plastic material, required surface finish, and expected production volume. Shorter lead times or high-precision requirements can also increase costs.

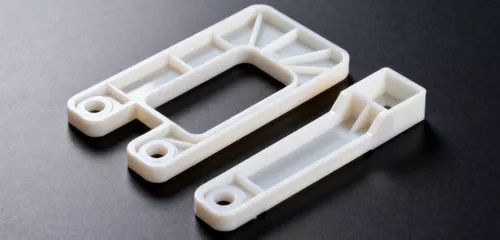

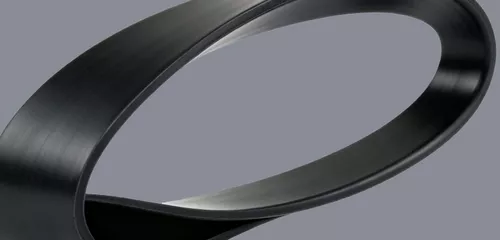

Custom Plastic Injection Molding Services

As a premium precision plastic iniection molding manufacturer in USA operating from china, we deliver end-to-engservices--from concept to finished mold,ensuring your products reach the market faster with uncompromising quality.

◉Part Production From1-1,000,000+ Parts

◉Over 100 Thermoplastics

◉Rapid Tooling: 15–30 Days

Get An Instant Quote