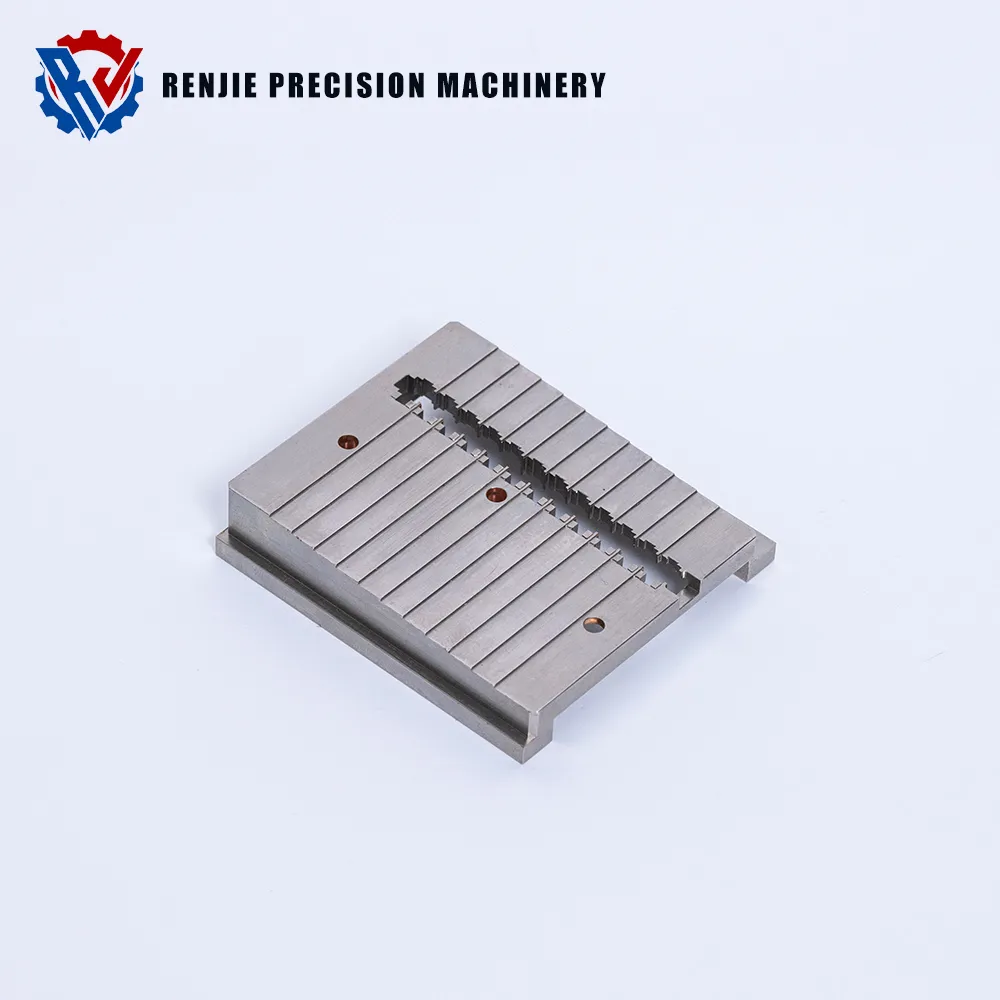

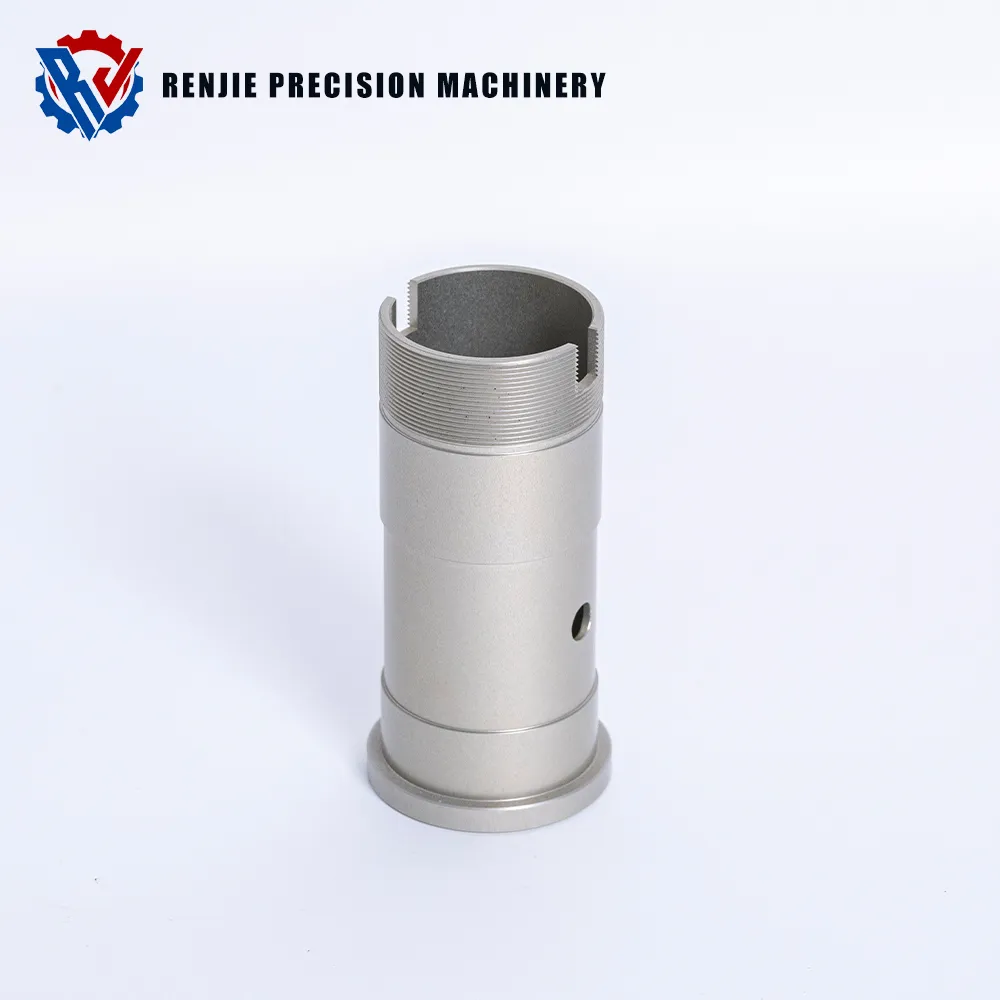

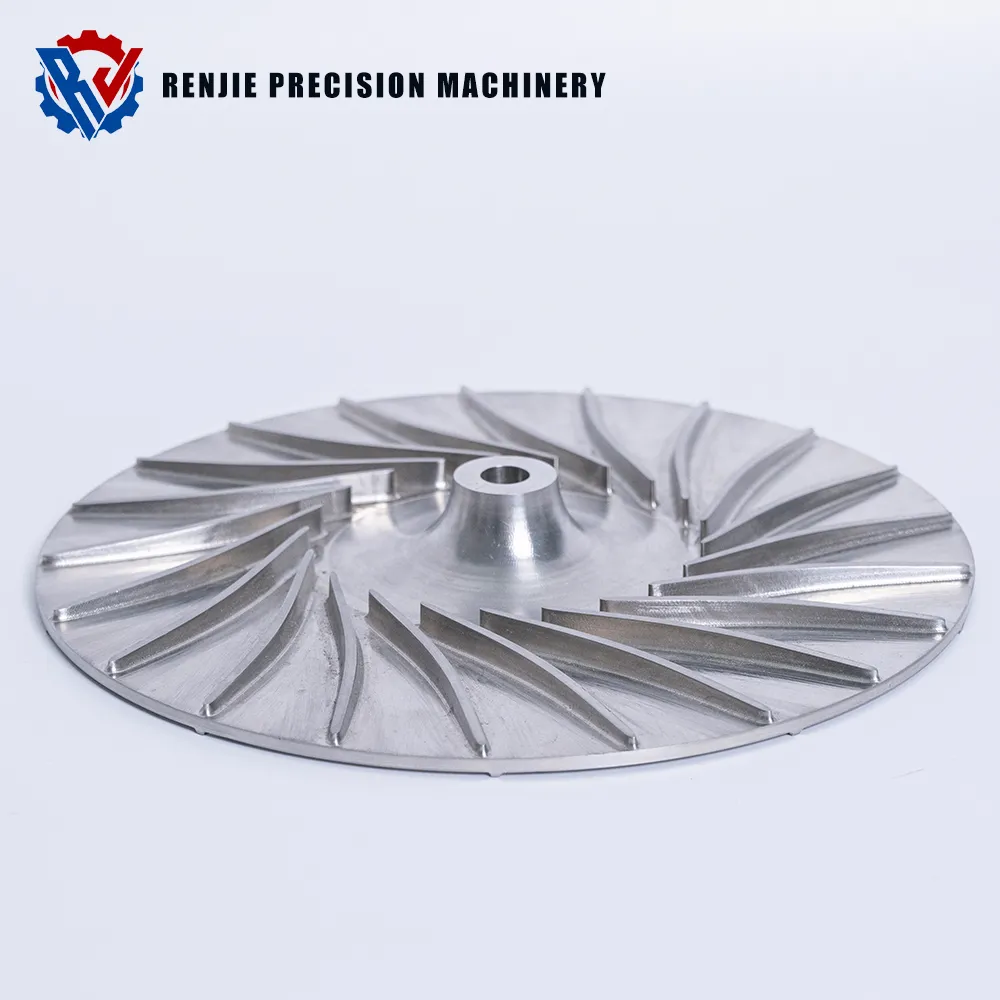

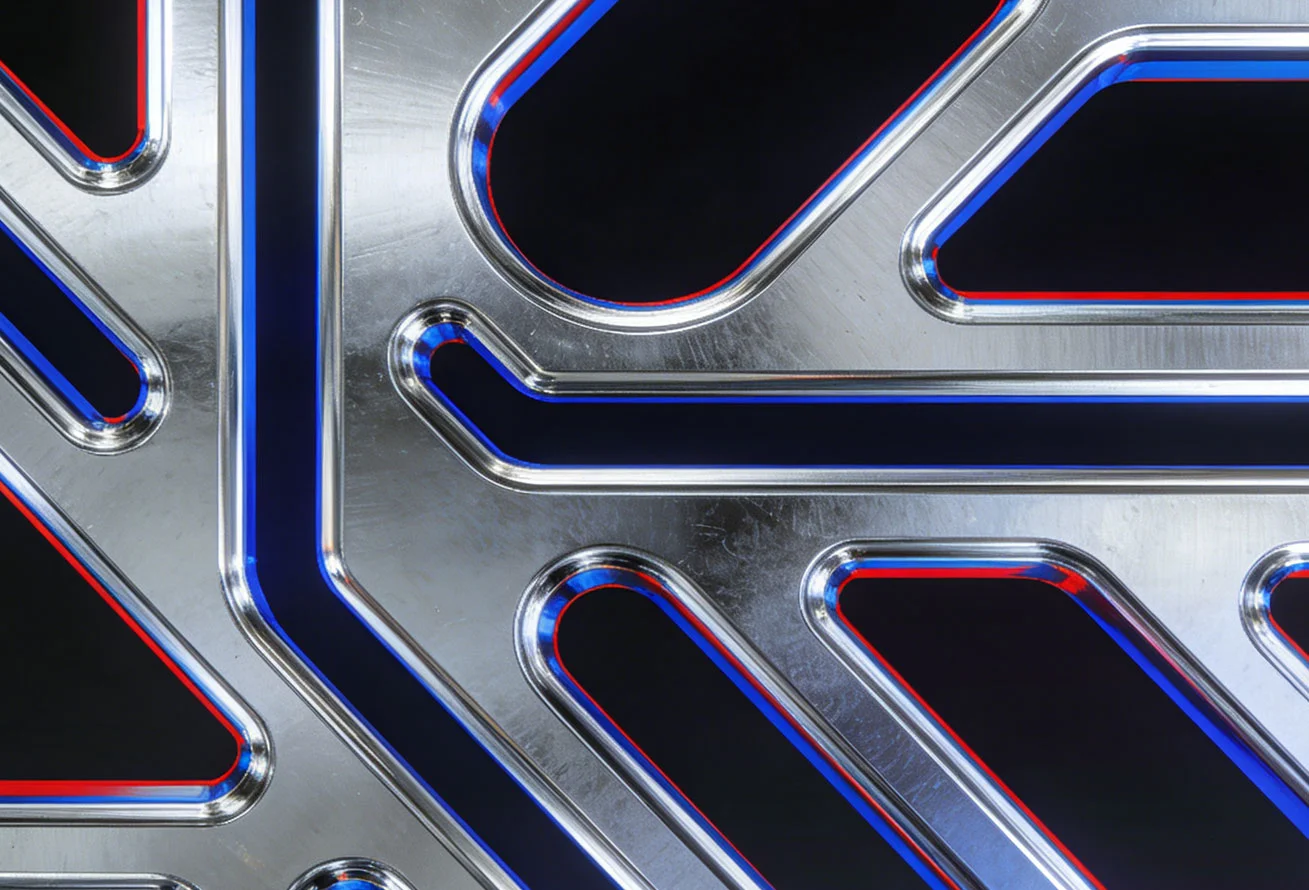

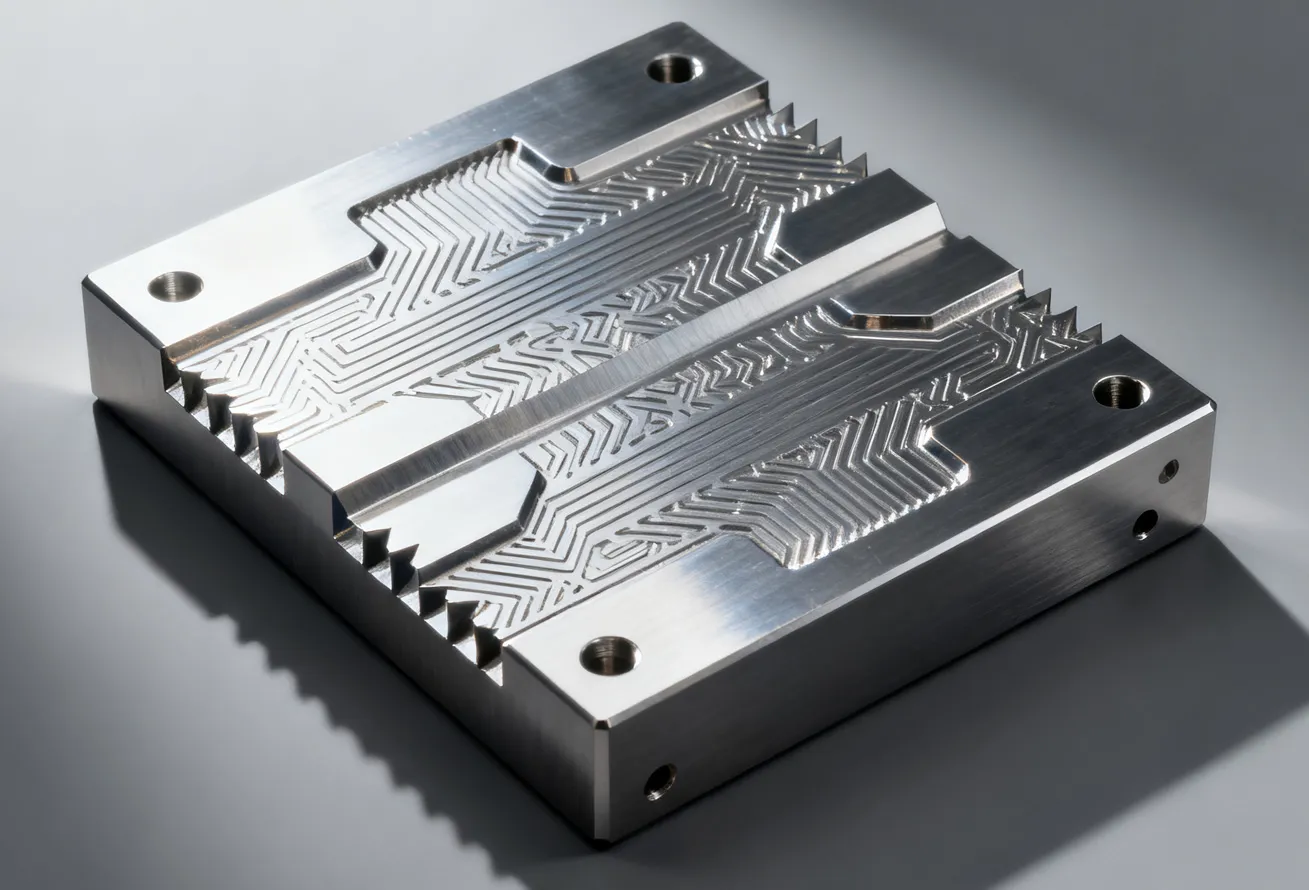

In order to ensure the accuracy and quality of products, the company is equipped with five-axis link age machining centerturning and milling compound, drilling and tapping machine CNC machine tools,CNC lathes, qeneral turning, milling machine grinding machine,coordinate detector, quadratic element, height meter and other advanced processing equipment and testing equipment.

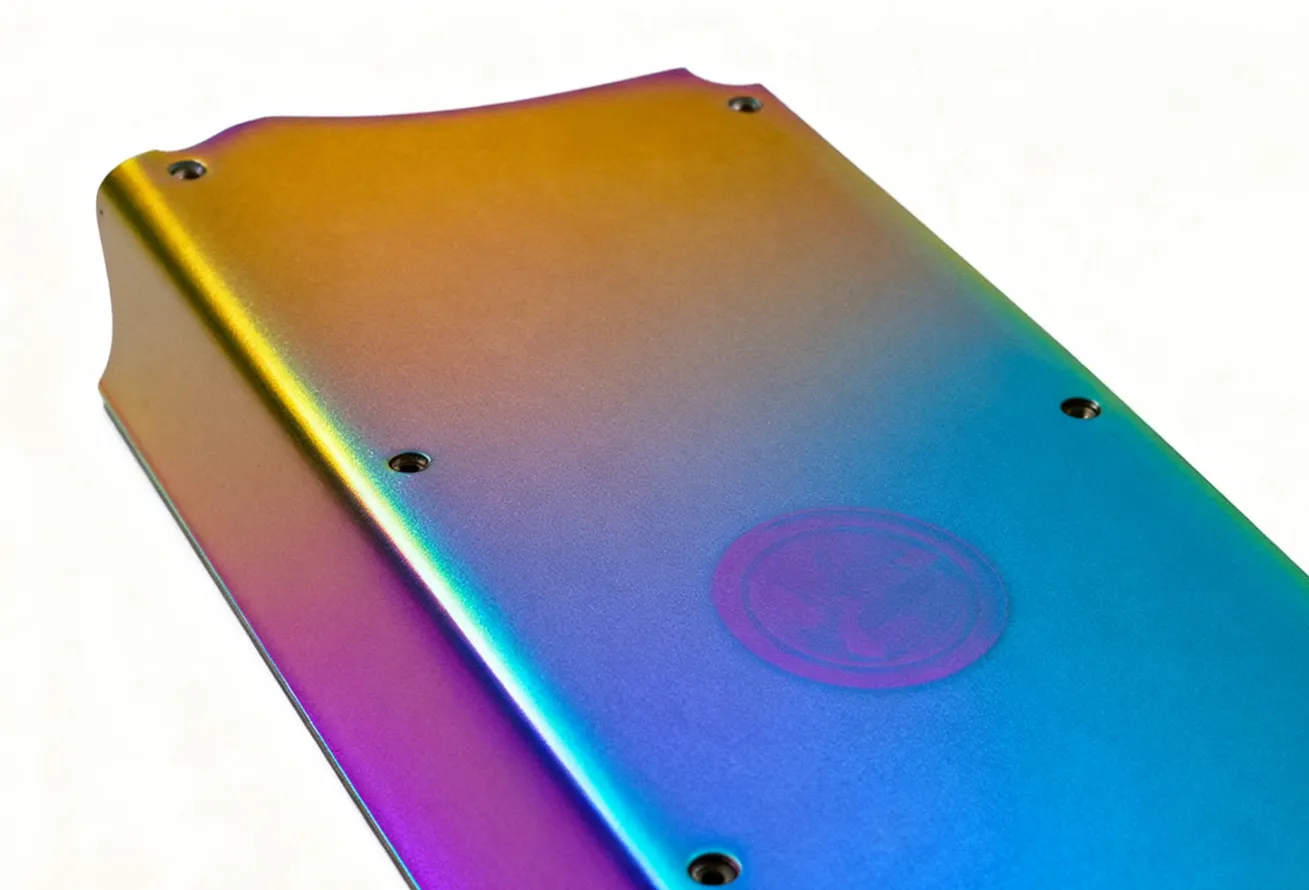

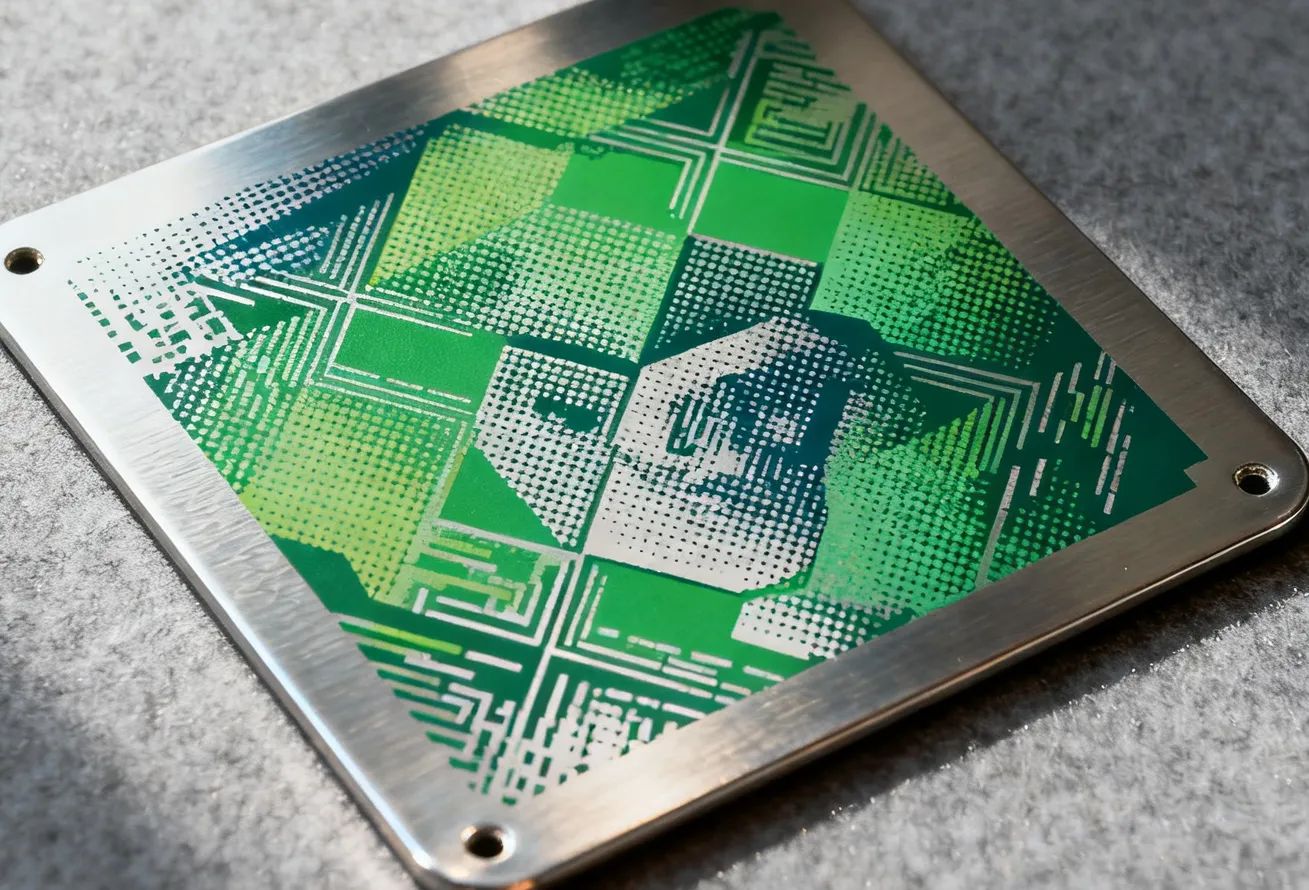

Custom Online Cnc Precision Machining Services

Need precision parts? We provide online CNC machining services from China, combining cost efficiency with quick turnaround. As a CNC precision machining manufacturer for USA and global markets, we deliver high-quality parts that meet strict industry standards. Simply upload your CAD files to get an instant quote today!

◉ISO 9001 & ISO 13485 Medical certified

◉Earliest delivery time within 7 days

◉Tolerances up to ±0.01mm (±0.0004")

Get An Instant Quote