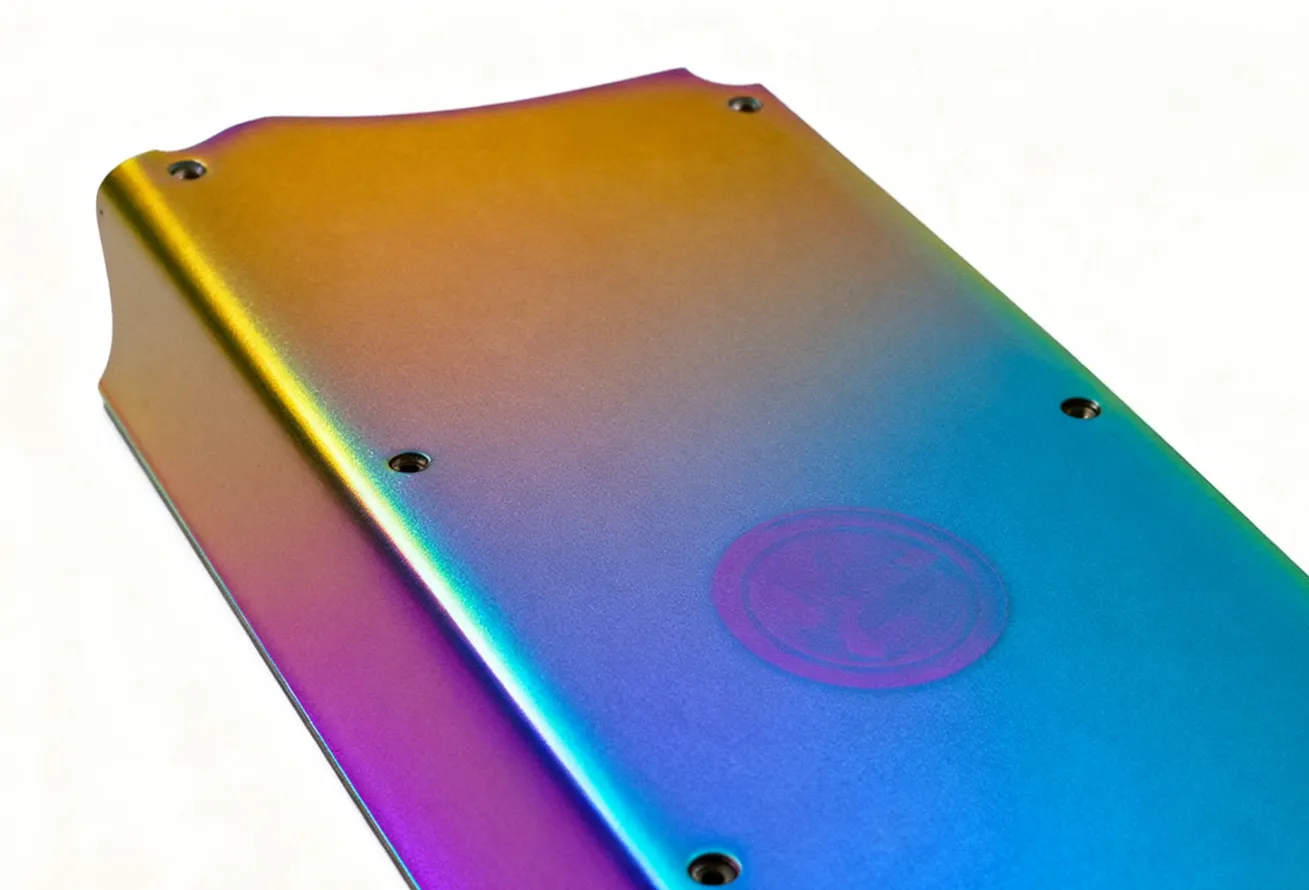

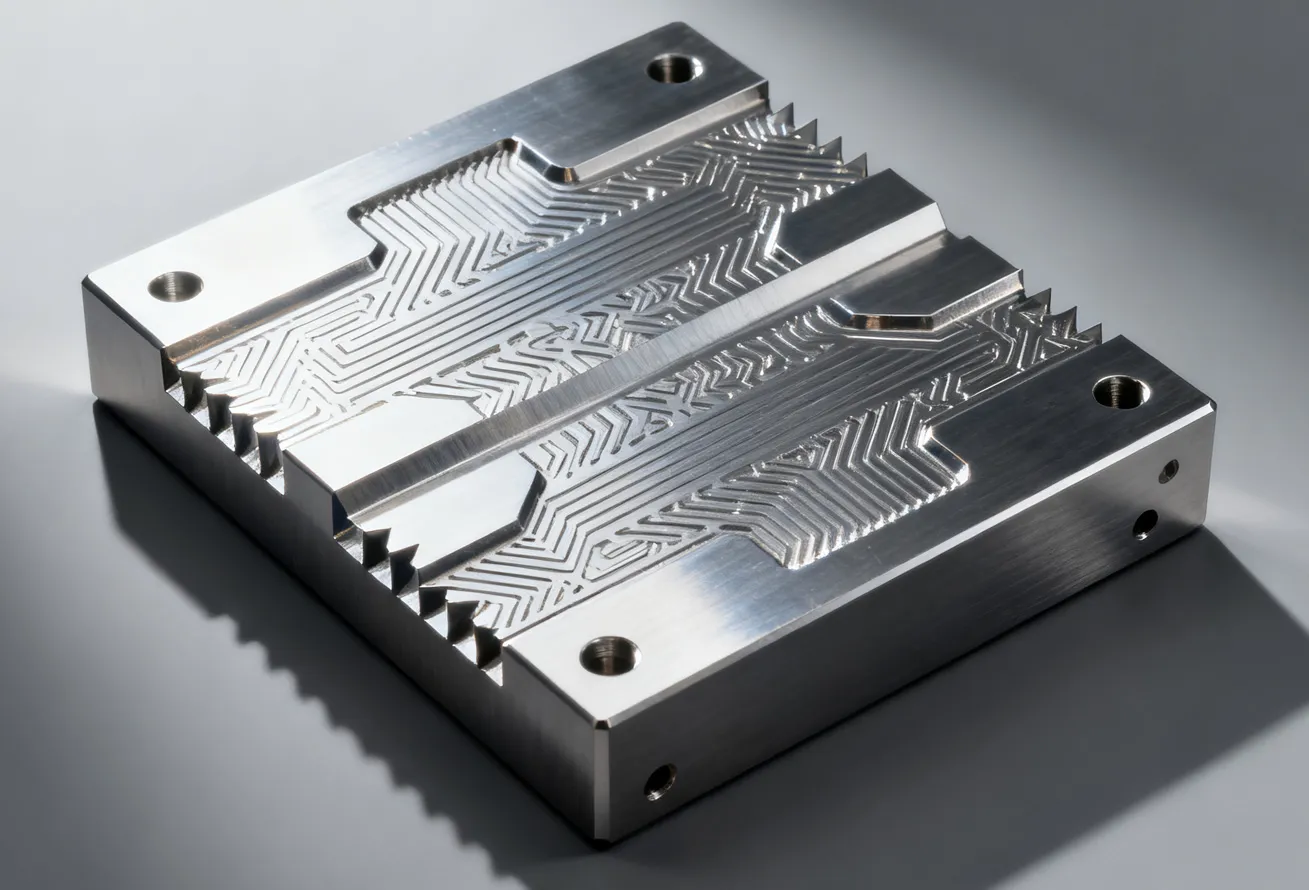

Our advanced online CNC machining services offer the flexibility to meet your design needs and development timelines. We produce prototypes, test parts, and low-volume production runs with the speed and accuracy needed for modern product development.

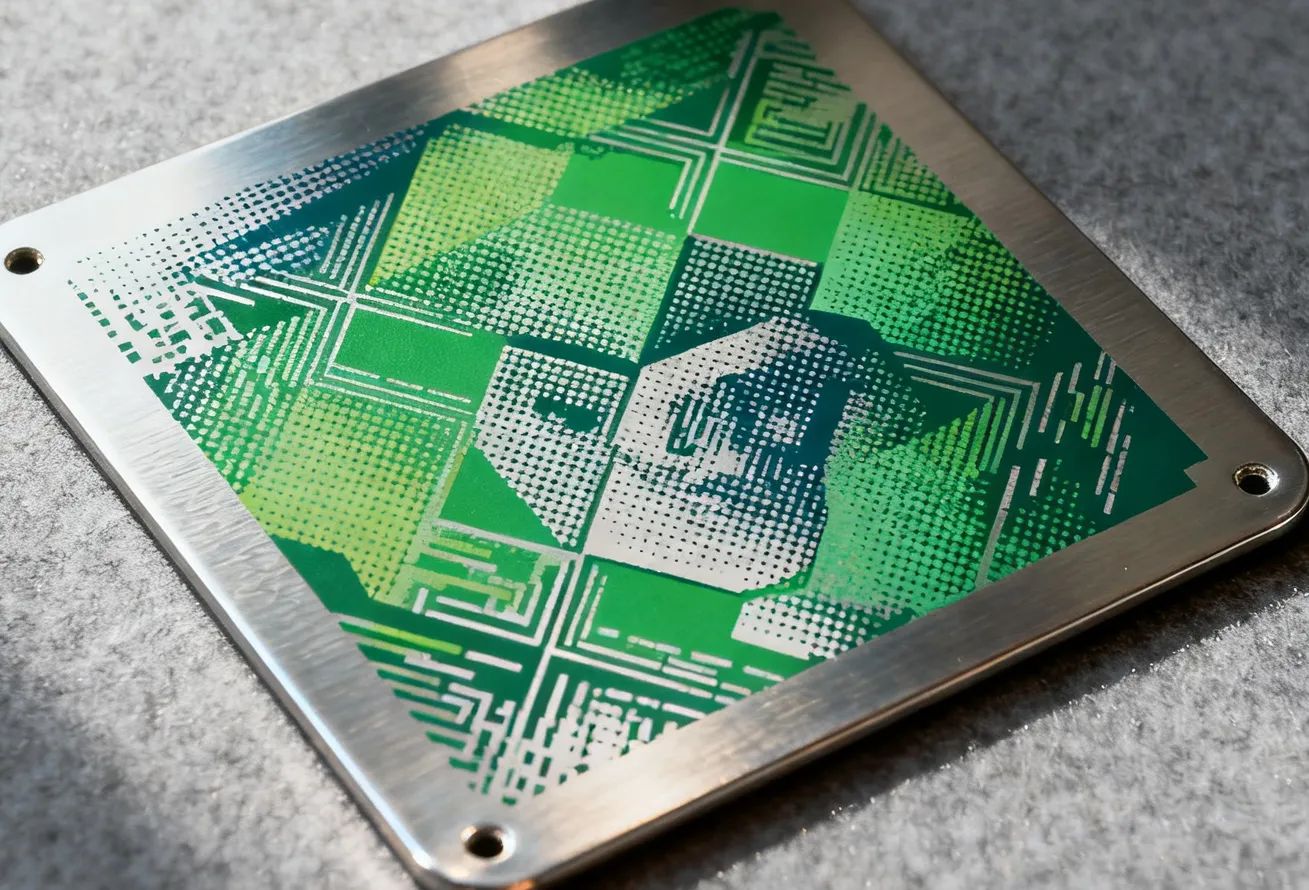

Online High Precision Cnc Milling Services

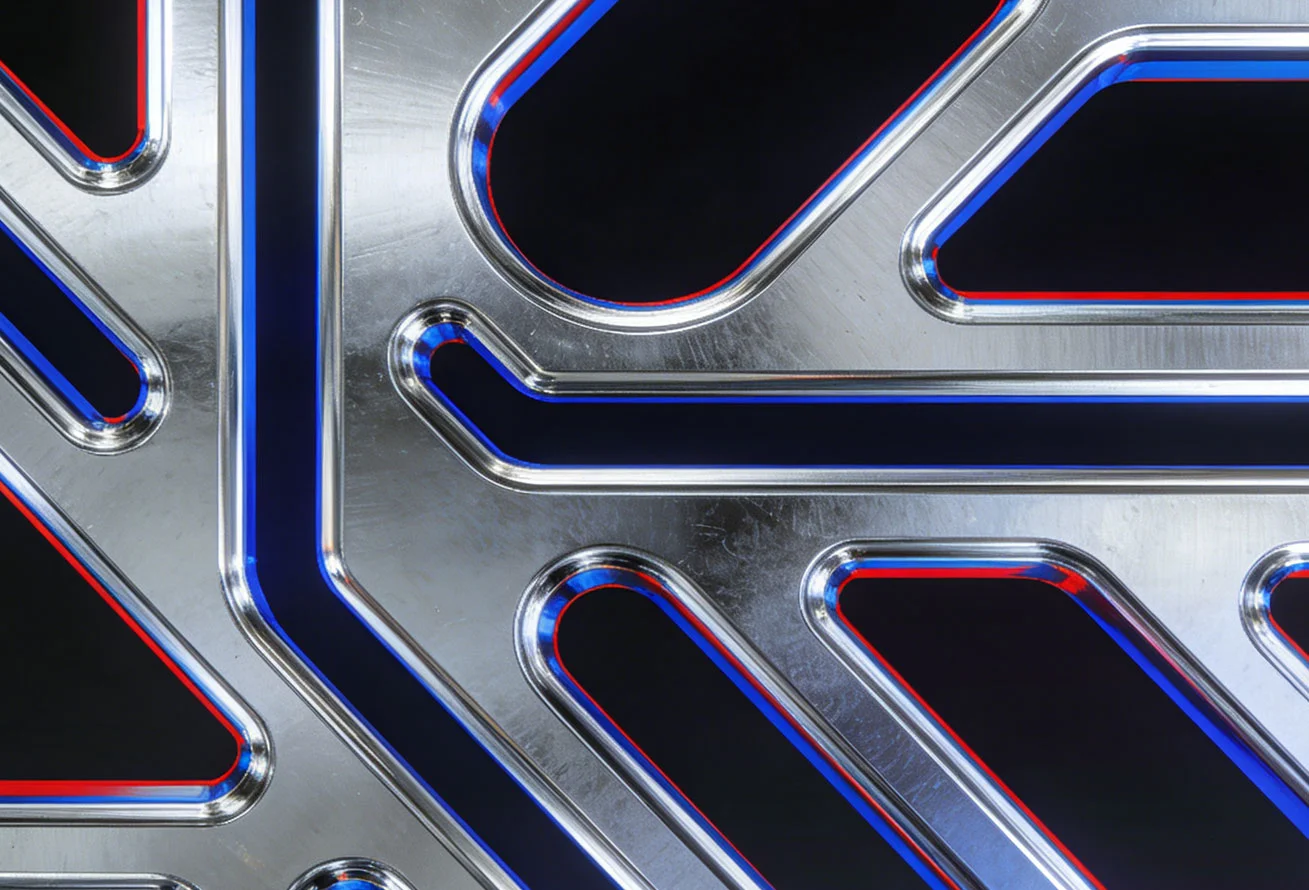

Rinjie is equipped with 3-axis, 4-axis, and 5-axis milling machines to efficiently handle complex, high-precision parts. We offer professional cnc milling service from china with instant online quotations (within 8 hours), superior-quality manufacturing, and fast, reliable delivery.

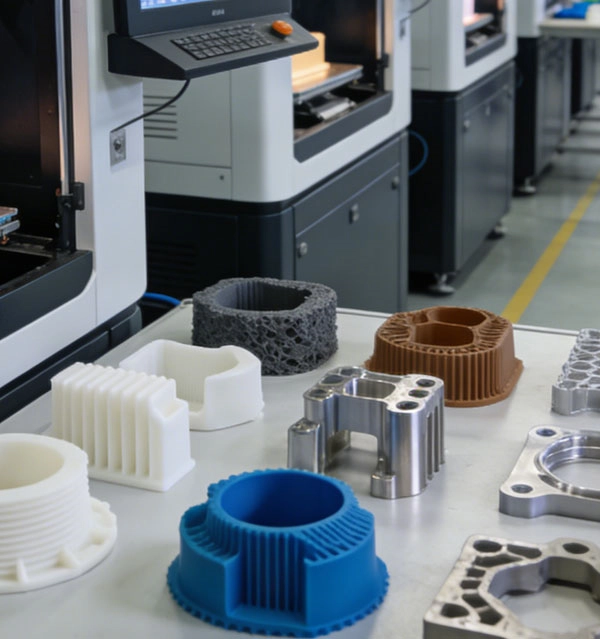

◉Support for One-Off & small Batch order

◉100 + metal & plastics material avalible

◉Tight Tolerances

Get An Instant Quote