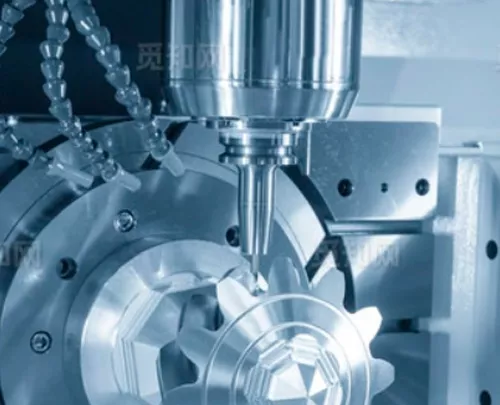

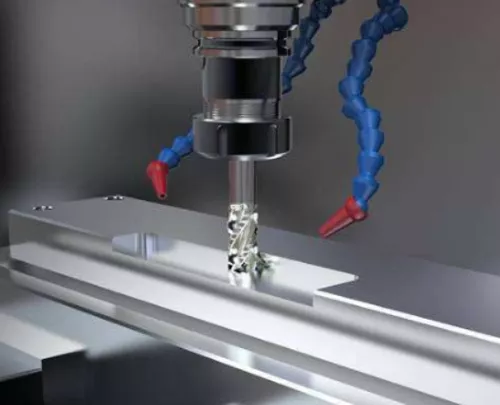

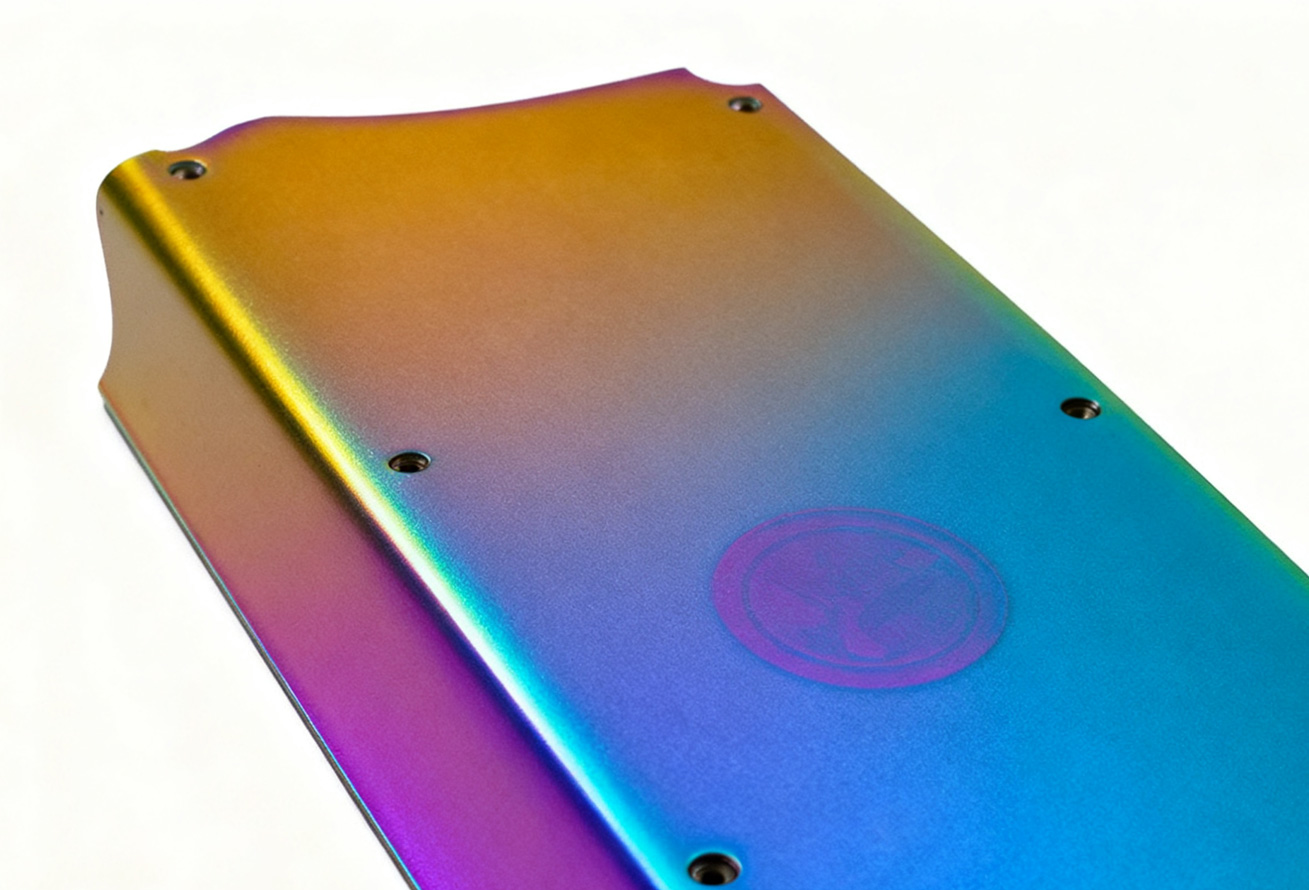

We provide a wide selection of CNC milling materials, ranging from titanium, aluminum, and stainless steel to high-performance insulating plastics. By partnering with trusted Materials suppliers, we carefully source premium materials to ensure quality for every project. Contact us.

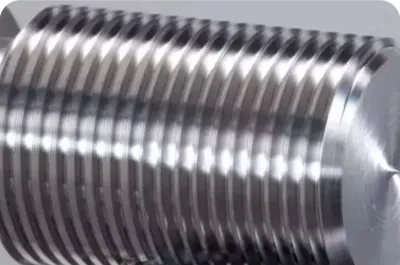

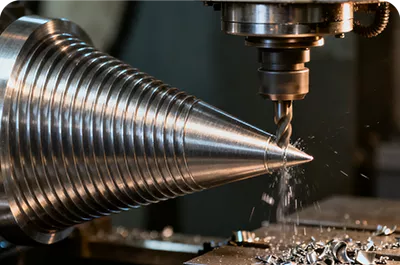

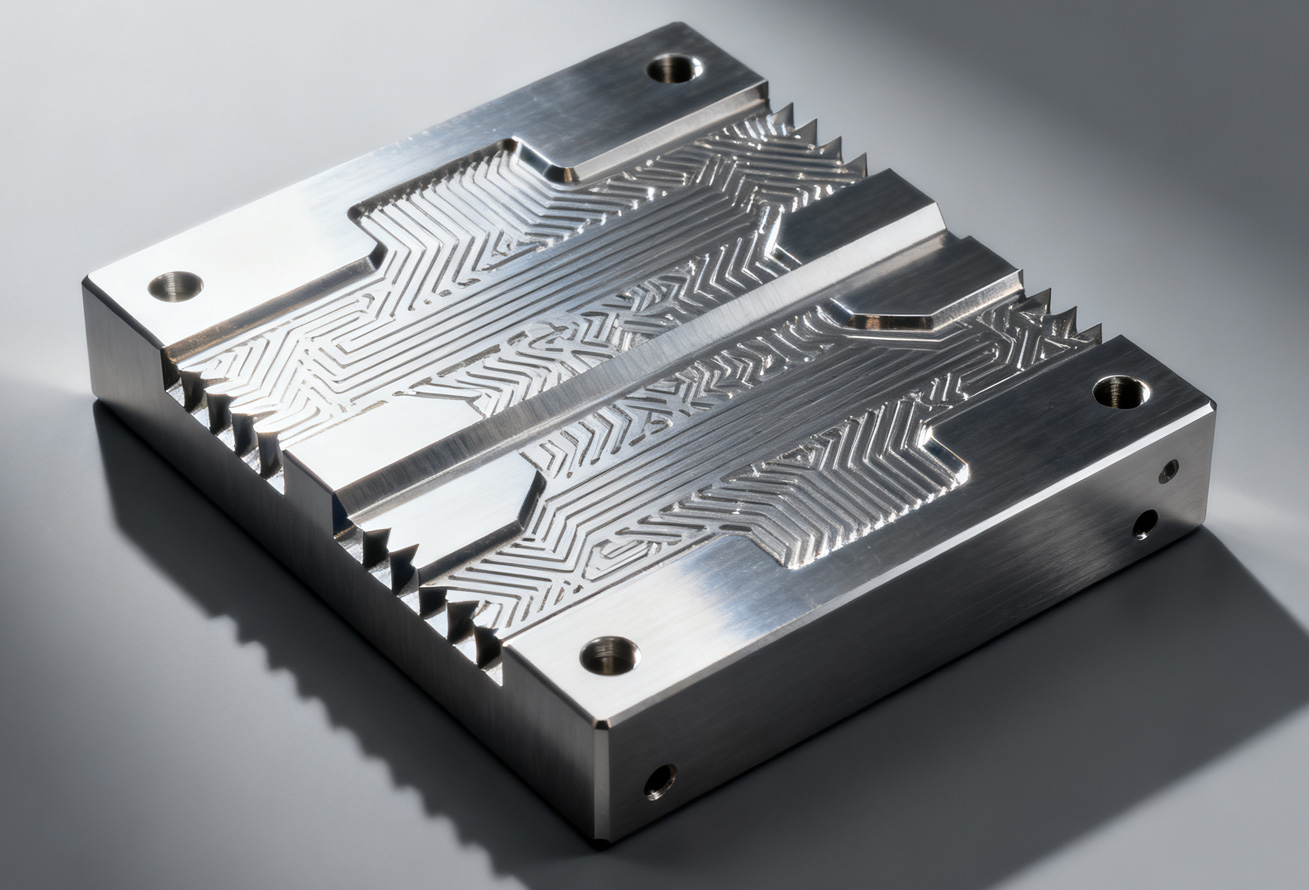

OEM Precision CNC Turning Services

Rinjie is equipped with CNC lathes, turning centers, and conventional lathes to handle complex, custom-turned parts. We provide instant cnc turning online quote services, advanced processing for intricate shapes, and free inspection reports.

◉Support for One-Off & small Batch order

◉ISO 9001 & ISO 13485 Medical certified

◉Tolerances to ±0.01mm(±0.0004)

Get An Instant Quote