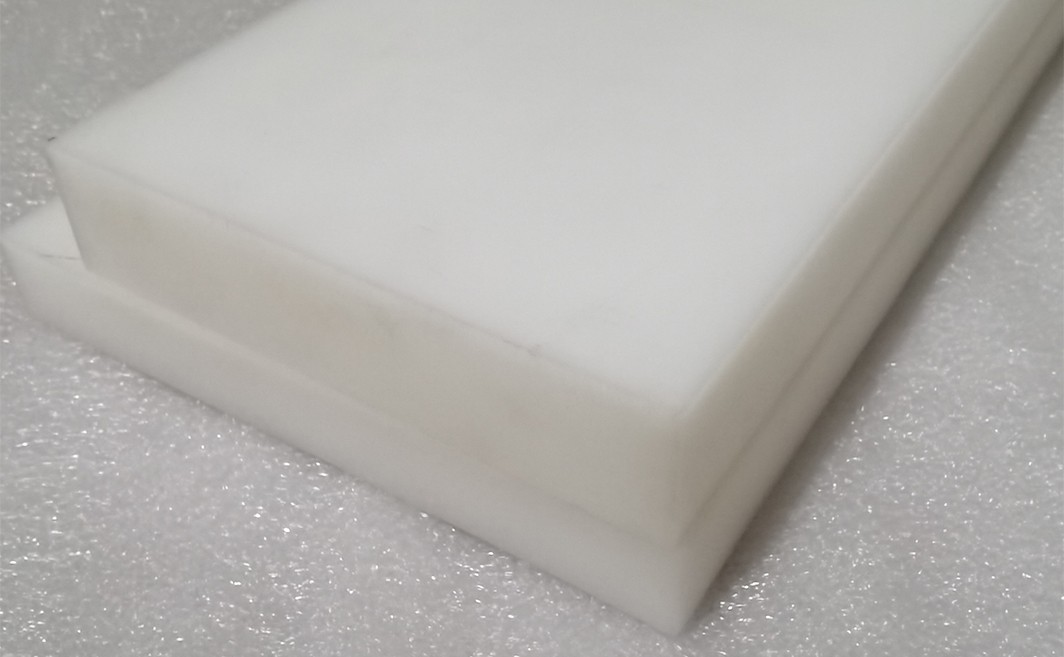

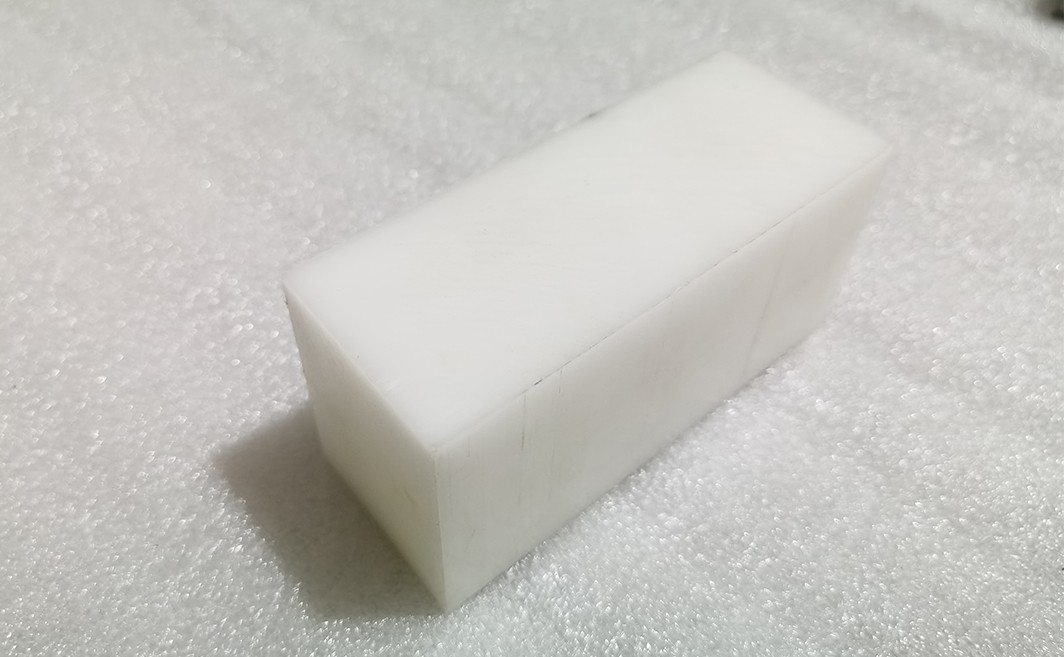

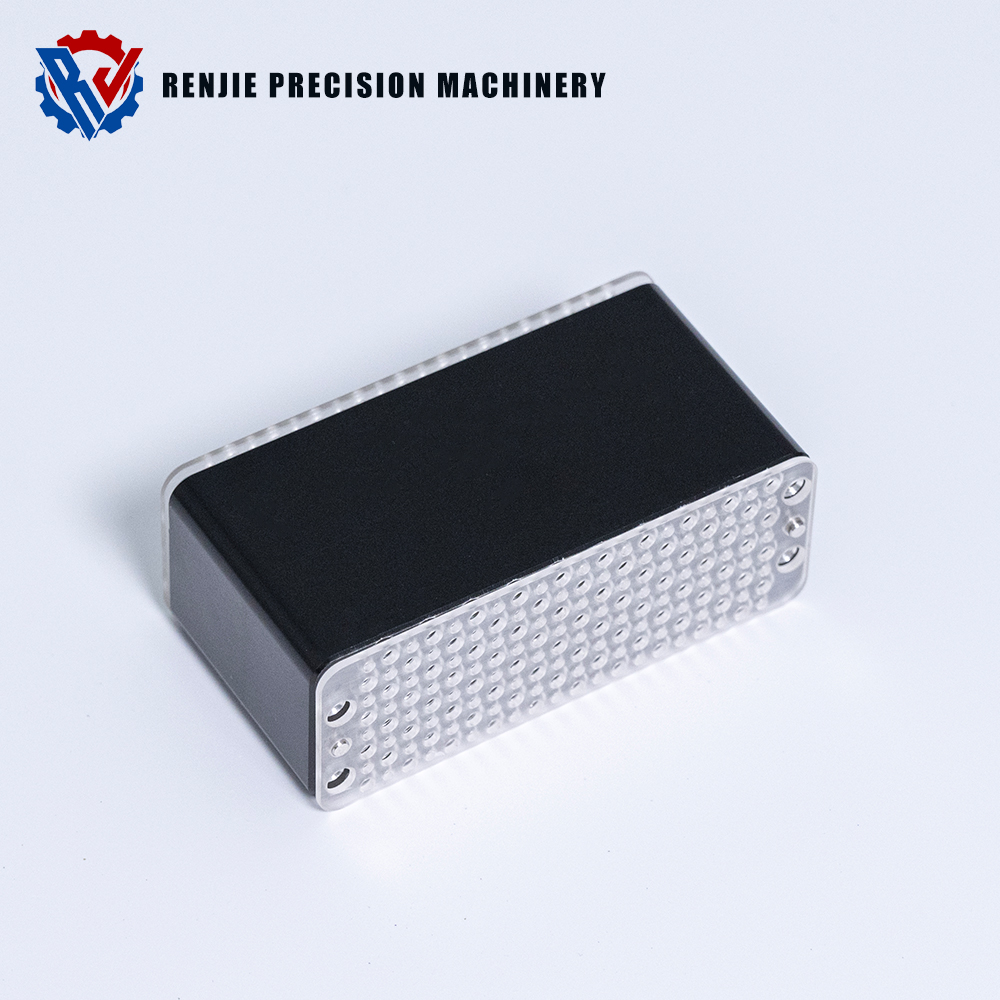

ABS

It is a thermoplastic polymer structural material with high strength, good toughness and easy processing. It is also a low-cost engineering plastic with good processing performance, strong mechanical properties, and a wide range of applications, making it an excellent choice for production parts.