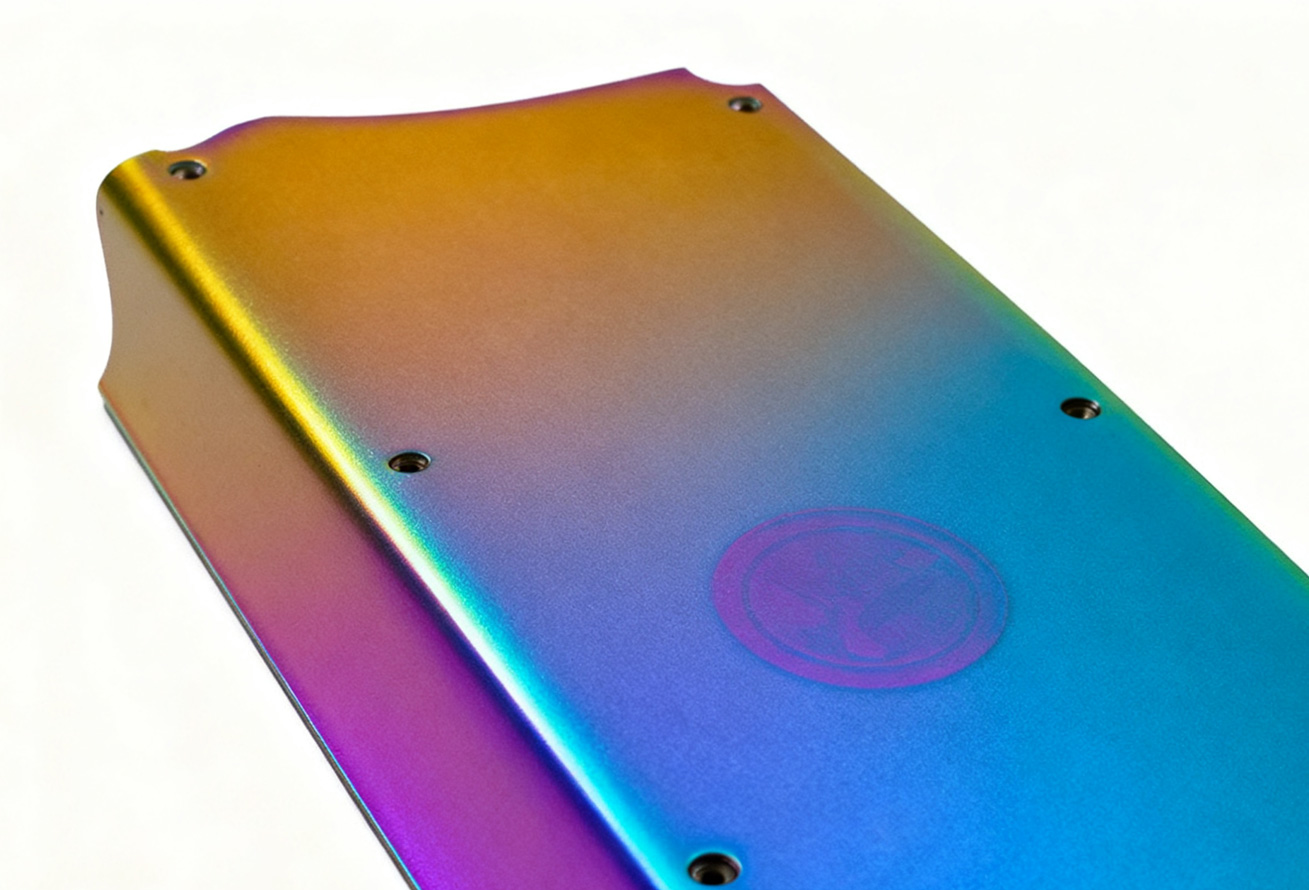

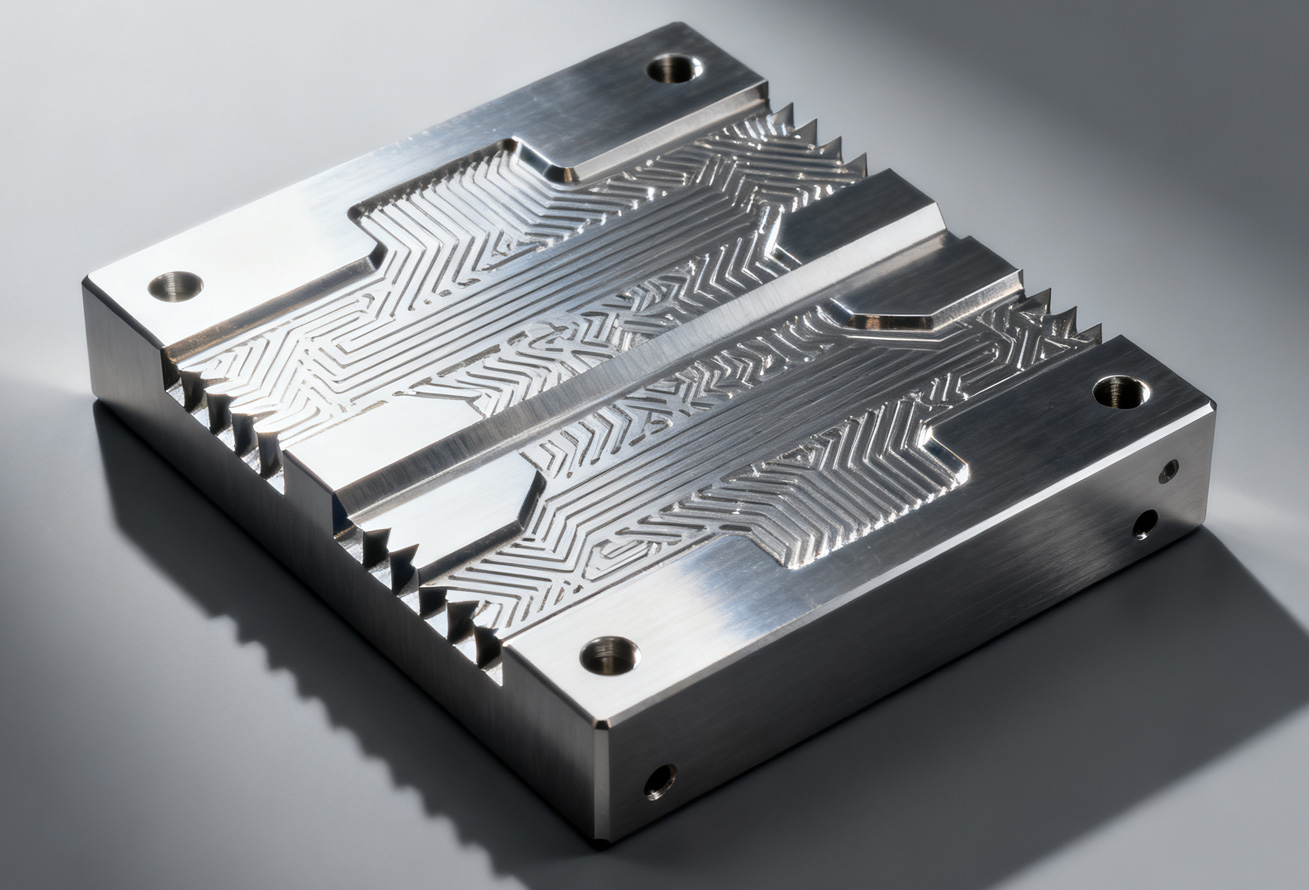

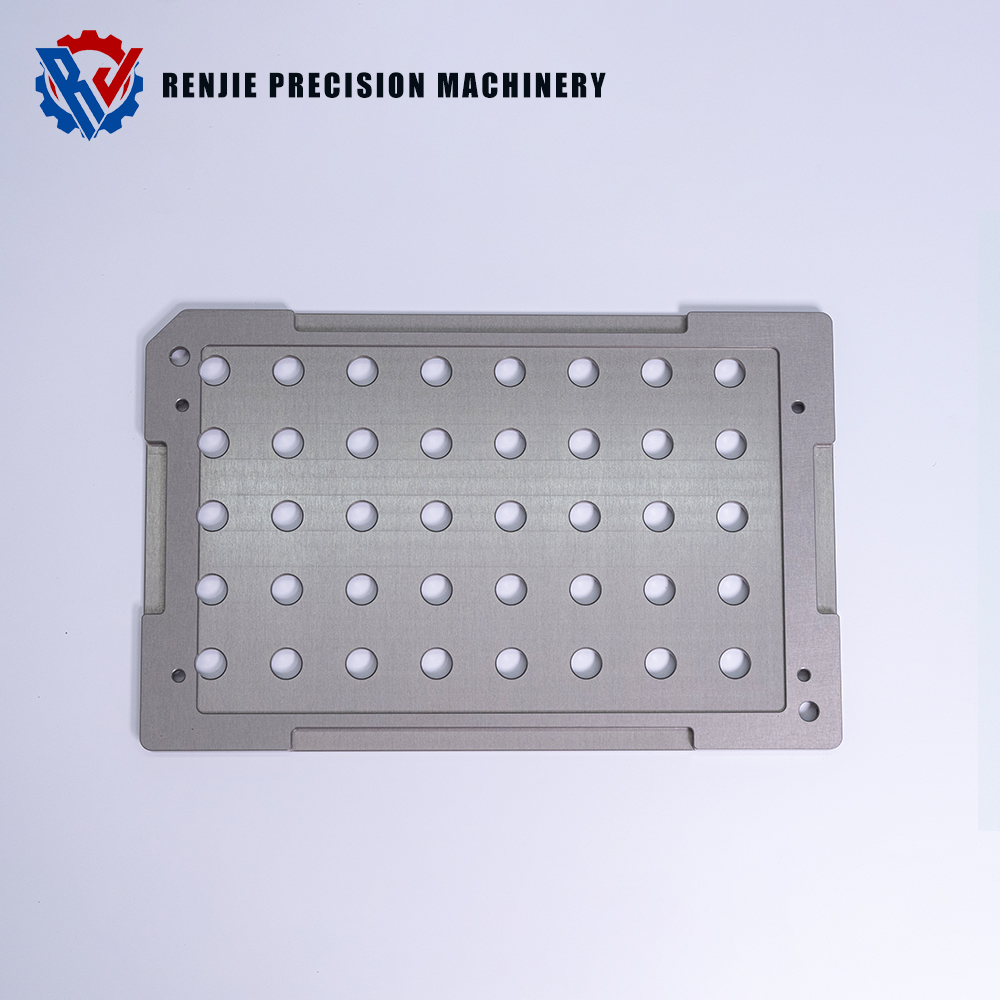

A:The common materials used in sheet metal processing include cold-rolled sheet, hot-rolled sheet, galvanized sheet, copper bronze, purple copper, beryllium copper, aluminum sheet, aluminum profile, stainless steel (mirror finish, brushed finish, matte finish). The choice of materials varies depending on the function of the product. Generally, it is necessary to consider the product's purpose and cost.

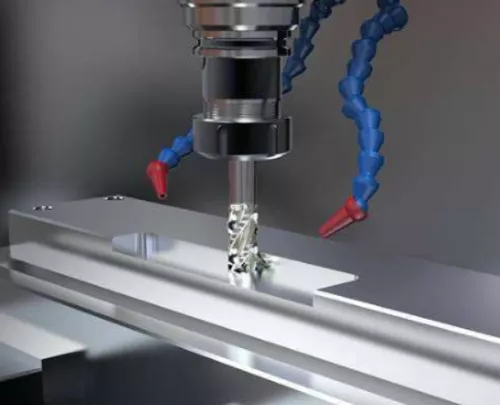

Online Custom Sheet Metal Fabrication Services

We ofer professional online sheet metal fabrication services in the UsA, including laser cutting, bending & forming, and welding,etc. Upload your design to get a fast,custom sheet metal fabrication service quotes today!

◉Support for One-Off & small Batch order

◉Tight Tolerances, Every Piece

◉ISO 9001 & ISO 13485 Medical certified

Get An Instant Quote